Bega Special Tools

Schorsweg 15 / NL - 8171 ME Vaassen

Bega Special Tools

We are manufacturer and distributor of Solutions for maintenance of rolling stock in the railway and subway industry: removing and installing bearing rings, railway bearings (TBU and SP bearing sets), train wheels, train rims, bearing rings, labyrinth rings, inner rings (NU-NJ bearings) brakes, gears, repair of Bogie sets.

Improve working conditions, safety first regulations

Get the job done efficiently, to save time

Prevent damage to machines and/or parts to be assembled or disassembled

Improve the quality of maintenance

Prevent damage to machines through correct assembly and disassembly

visit our website

MAINTENANCE EQUIPMENT FOR WORKSHOPS ROLLING STOCK

Removing and installing:

Bearing rings

Labyrinth seals

Railway bearings (TBU and SP bearing sets)

Train wheels

Train rims

Bearing rings

Inner rings (NU-NJ bearings)

Brakes

Gears

Repair Bogie sets

Railway

Assembly and Disassembly with BETEX MF Quick-Heaters

Bearing rings, railway bearings (TBU and SP bearing sets), train wheels, train rims, bearing rings, labyrinth seals, inner rings (NU-NJ bearings) brakes, gears etc. Repair Bogie sets.

Our BETEX MF Quick-heaters are state-of-the-art Mid-Frequency Induction Heaters for both assembly and disassembly. Many applications are possible. With this safe and cost-effective technology, you can quickly heat all kinds of components to remove or mount. Our new generation of Mid-frequent heaters 3.0, are equipped with smart process technology. The new heating system allows a far better control of the heating process and data storage for future reference. These heaters enable users to perform safe, fast and clean operations.They feature adjustable power control and double temperature measurement

(monitoring Δ T).

Railway

Removal & installation with BETEX BPP Bearing Puller Pusher

Installation and removal of railway bearings (TBU, SP and TAROL bearing sets). Specially for rail- and metro workshops. This hydraulic aid will allow you to save valuable time and work safe & efficient. Easy to use roll-around model, also available as compact side-shift model.

- mobile and easy to use by one person

- 100 ton pulling capacity

- 68 ton pushing capacity

- suitable for locomotives, passenger and freight cars

- for safe, simple and fast mounting and dismounting of tapered roller bearings

- for assembly of TBU and SP bearing

Railway

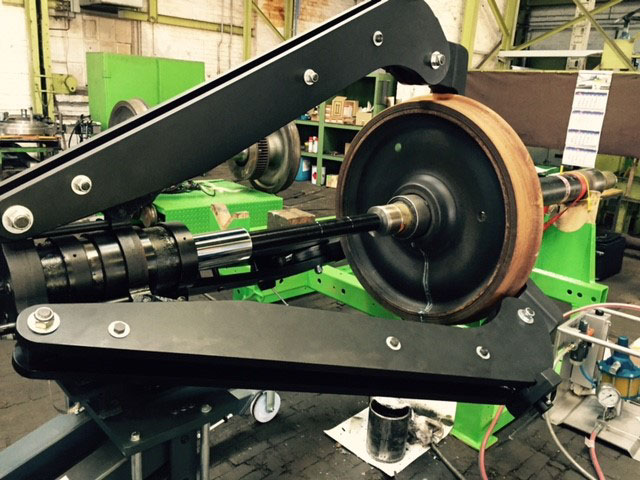

Dismounting trainwheel with BETEX HXPM mobile hydraulic pullers and oilpressure

Self-centering (extra safety!) 2 or 3 arm puller, 50, 100 or 150 ton capacity. For dismounting of all kinds of transmission parts such as bearings, couplings, gears, wheels etc. The puller is self-centering, easy to manoeuvre and adjustable in height. Arms slide inwards or outwards simultaneously.

Watch the video and see how a train wheel is removed, using a combination of oil pressure and hydraulic pulling force.

A high pressure pump (BETEX UHAP2800 Ultra) is used to create an oil film. Oil is pressed into the wheel bore and axle. Next, a hydraulic puller (HXPM 100ton) is applied.

Due to the oil film the wheel is "floating" and pulling it off the axle is now an easy job, without damage to shaft or wheel bore.

This method is fast, efficient and practical to use in workshops for maintenance of rolling stock: Locomotives, Trains, Trams and Metro.