WE OFFER A COMPLETE SOLUTION

LaborexRail is specialized in the development and production of vacuum wastewater units for the daily maintenance of trains. We ensure that faeces and wastewater from the lavatory areas can be removed via several suction posts all connected to one central unit. Besides emptying the wastewater tanks, each suction post can be equipped with:

• vacuum cleaning hose to clean the carpets

• rinsing hose to rinse the tanks

• hose to add “blue product”, typical for high speed rail

• water to provide the train with fresh Water

• heated soapy water for cleaning activities

• compressed air formaintenance and repair

• 2 electrical outlets

THIS UNIQUE PATENTED SOLUTION MAKES IT POSSIBLE TO EVACUATE FAECES AND CARPET DUST THROUGHOUT THE SAME EVACUATING PIPELINES.

RAILWAY VACUUM WASTEWATER SYSTEM IN OPERATION

SUPPLY AND DISPOSAL NETWORK FOR TRAIN AND HS DEPOTS

LaborexRail supply and disposal networks for train depots are configured to meet every requirement. We consider all factors such as toilet technology, hygiene needs, typical weather conditions, automation requirements, etc.

MOBILE DISPOSAL VEHICLES

We have a wide range of self-propelled electric vehicles and trailers. All LaborexRail mobile disposal systems have a maximum flexibility and are easy to handle and light in weight.

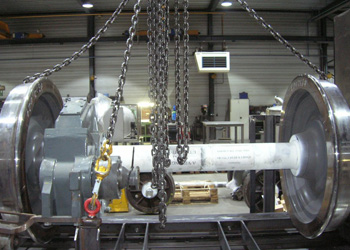

RAILWAY BLASTING CABINETS

Our blasting cabinets are produced according to the latest environmental, safety, hygiene and ergonomics standards. We ensure that the power of our blasting cabinets is as low as possible when blasting your railway parts. By the continuous recycling of the blasting media, we also have a low consumption. The railway parts are blasted in closed blasting cabinets. Thus, the workspace is always clean and dust free.

RAILWAY CLEANING SYSTEMS

RAILWAY CLEANING

The purity requirements play an important role in the railway industry. The railway industry develops and renews itself constantly, as a result of which the parts ask a deeper and more careful cleaning. A dirt particle can lead to mechanical failure or other serious defects. Therefore we constantly strive to make our railway cleaning systems meet the highest purity requirements and norms.

All our railway cleaning systems are developed and manufactured in-house, which results in high quality products. They comply with the CE machinery directive and are characterized by their reliability.

AFTER-SALES SERVICE

Even after the purchase of your railway cleaning system, we continue to follow up. We have a permanent team available for supply and installation. Besides that, there is another team that provides professional maintenance.

Our service trucks are fully equipped. We guarantee an excellent after sales service. This means most situations are handled at once. Certain railway cleaning systems work via remote monitoring.

MAINTENANCE CONTRACT

For peace of mind, most customers sign a maintenance contract with us. Through conducting regular rail maintenance, we avoid unexpected machine failures and thus high costs and also the life of your cleaning system increases considerably.

MORE THAN 4,000 PARTS IN STOCK

We have a large warehouse where over 4,000 parts are in stock. Should your machine fail, we can guarantee that your cleaning system will be operating again within 24 hours. In certain circumstances and emergencies, bridging machines can be placed to keep your production running.

RAILWAY VACUUM WASTEWATER SYSTEMS AND CLEANING MACHINES

MORE THAN 50 YEARS OF EXPERIENCE IN COLLABORATION WITH RAILWAYS