Comment

How a railway’s data needs change throughout its life cycle

James McLaughlin, senior business development manager for rail survey at Fugro, on the benefits of train-borne survey technology.

A RILA® system mounted onto in-service Scotrail passenger trains. Credit: Fugro

The UK rail network is an essential part of the national infrastructure, ensuring millions of passengers and freight move efficiently every day. Yet maintaining a safe, reliable, and modern railway system depends on vast amounts of accurate data.

From track alignment and platform compliance to electrification and vegetation management, railway operators require precise measurements to enable predictive maintenance and keep the permanent way running.

James McLaughlin, senior business development manager for rail survey, Fugro

Historically, acquiring this data has been a complex challenge. Manual surveys require track access, and that usually means surveying at night to avoid disrupting services – increasing the time required, as well as adding logistical challenges.

Even then, traditional methods struggle to provide the necessary level of accuracy required for dynamic railway management. As railway networks expand and evolve, the demand for high-quality, efficiently collected data has never been greater.

The importance of absolute track position

One of the biggest challenges in railway data collection is understanding the absolute position of the track. Every measurement – from clearance analysis to structural gauging – depends on knowing exactly where the track sits in relation to surrounding infrastructure.

Without this foundational data, operators face difficulties in assessing changes over time, integrating new developments, or ensuring compliance with safety and operational standards.

Train with RILA sensor on Glenfinnan viaduct, Scotland. Credit: Fugro

Physical track surveys, though once the standard, often fail to provide the flexibility required to meet these evolving needs. Slow, manual measurements leave little room for responsive action, limiting operators’ ability to make decisions based on up-to-date insights.

A full lifecycle approach to railway data collection

Rail infrastructure evolves through various phases, requiring adaptive data collection methods to support planning, construction, operation, and renewal. Accurate, high-precision insights are essential for informed decision-making throughout this lifecycle, ensuring railway networks remain efficient, safe, and future-ready.

For example, this data could help to prioritise and plan track renewal projects, or determine the heights and clearance of existing platforms, electrification or signalling assets or other station infrastructure to identify where improvements need to be made, and by how much.

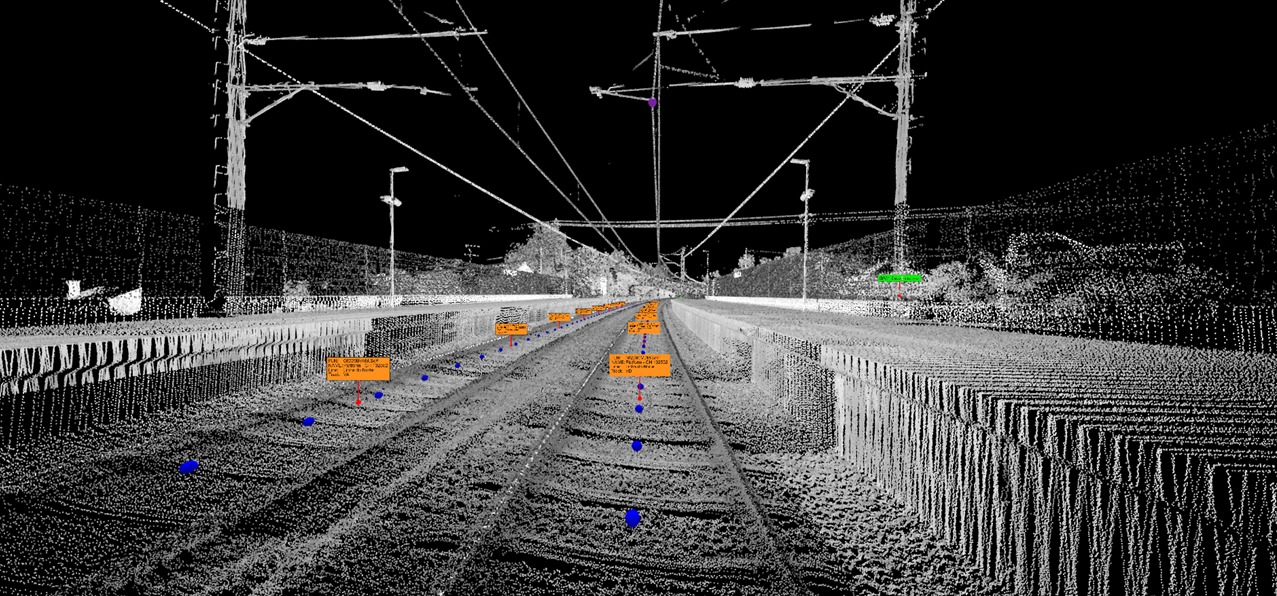

An example of a data image showing the fusion of different RILA® data streams. Credit: Fugro

By embedding high-quality data collection into each phase, railway operators can take a lifecycle-driven approach that strengthens safety, efficiency, and infrastructure resilience.

Key benefits of survey technology

To meet the demands of modernisation and uphold critical operational standards, railway operators are adopting advanced technologies.

Fugro’s train-borne survey technology is being used to create a highly accurate, information-rich model of railway infrastructure. By mounting directly to in-service trains, it takes advantage of existing service capacity to collect data faster.

Traditional surveys often require personnel to access live railway tracks, creating a range of challenges from risk assessments to operating night shifts. Train-borne survey technology minimises human exposure by collecting data remotely, significantly improving workforce safety and reducing reliance on hazardous surveying methods.

Manual surveys often need track access at night, restricting operators to short windows for asset assessment and maintenance. Open line working, where crews operate directly on live train tracks, is now banned, further limiting traditional surveying options.

With train-borne survey technology, data can be collected at full line speed, reducing track possession as well as acquisition time. Simply attaching to the front of an in-service train also allows more frequent surveys to be carried out, allowing operators to always have the most up-to-date picture of current conditions.

Forward-facing video footage captured by RILA®. Credit: Fugro

Train-borne survey technology provides highly accurate measurements, allowing operators to analyse track geometry, gauge distances, and monitor clearance with confidence, ensuring compliance and long-term rail viability.

While manual data processing is susceptible to errors and delays, the data acquired by train-borne survey technology fuels automated workflows. This efficiency empowers railway operators to extract valuable insights with greater speed, directly incorporating processed data into their rail management platforms and building information models. This automation reduces human error, accelerates decision-making, and ensures railway operators always have access to the most relevant data.

With tools like train-borne survey technology, railway operators can transition from manual, time-intensive processes to an intelligent, automated approach that supports every phase of rail infrastructure management. In an industry where precision and efficiency are paramount, investing in reliable, high-quality railway data is not just an advantage – it’s a necessity.

The mine’s concentrator can produce around 240,000 tonnes of ore, including around 26,500 tonnes of rare earth oxides.

Gavin John Lockyer, CEO of Arafura Resources

Total annual production

Production challenges for rare earth supply chains

There are two key issues with the production of REEs. First, all the rare earth deposits are mixed together, so it is difficult and expensive for processors to separate them and to take advantage of their individual properties. It is similarly challenging to split up the more valuable ones, such as terbium, from those of little value, like lanthanum.

Second, REEs are bound up in mineral deposits with the low-level radioactive element, thorium, exposure to which has been linked to an increased risk of developing lung and pancreatic cancer.

These obstacles create a huge challenge for any Western company that wants to become involved in the industry. However, they must be overcome if the Western world is to end its dependence on China.

Caption. Credit:

The biggest rare earth mines are located in China, and this source of domestic production has helped drive Chinese dominance. The Bayan Obo deposit in Inner Mongolia, north China – containing 40 million tonnes of rare earths reserves – houses the world’s largest deposits. The mine has been in production since 1957 and currently accounts for more than 70% of China’s light REE production.

However, Western mines are aiming to change this balance of production and power. The Mountain Pass Mine, owned by MP Materials , a Las Vegas-based mining company, is an open-pit mine of rare earths on the south flank of the Clark Mountain Range, 85km south-west of Las Vegas. In 2020, the mine supplied 15.8% of the world’s rare earth production and is the only rare earth mining and processing facility in the US.

In October 2020, Donald Trump, the former US president, signed an executive order declaring a national emergency in the mining industry, aimed at boosting the domestic production of rare earths. Trump ordered his cabinet to study the matter, with a view towards giving government grants for production equipment and imposing tariffs, quotas or other import restrictions against China.

The move, it said, would “allow the US Government to leverage the resources of its closest allies to enrich US manufacturing and industrial base capabilities and increase the nation’s advantage in an environment of great competition”.

The move, it said, would “allow the US Government to leverage the resources of its closest allies to enrich US manufacturing and industrial base capabilities and increase the nation’s advantage in an environment of great competition”.