Proven solution for challenging projects

The use of stone wool for vibration control and structure protection in railways may seem relatively new or even counterintuitive. However, they have been successfully used to control ground-borne vibrations on railways in some of the harshest conditions in Scandinavia since the early 1970s. Rockdelta® stone wool mats are backed by over 80 years of experience in stone wool production and over 43 years of expertise in vibration control solutions. Today stone wool is the preferred solution for rail track vibration control and structure protection in Scandinavia and many other countries across the globe.

Project Citybanen Stockholm, Sweden

Vibration control: protecting people and buildings from harmful vibration

Rockdelta tackles vibrations annoyance by isolating the track and protecting nearby structures from ground-borne vibrations caused by rail transport systems: tramways, light rail systems, subways, metros, main lines and high-speed lines. Attenuation of vibration is achieved by decoupling the track from the surrounding environment using Rockdelta as a resilient mat.

Ballast and Subgrade protection: reducing ballast attrition and protecting the substructure by decoupling the ballast bed

Rockdelta mats may be used as well for decoupling the permanent way from the railroad formation to reduce ballast attrition, prolong the life of the ballast bed and limit maintenance activities by improving the distribution of the acting dynamic forces in traditional ballasted railways and bridges.

Rockdelta applications: the natural solution for every track

Rockdelta mats are designed, tested and manufactured to have an extended lifetime with retained functional performance even under extreme conditions. This helps ensure the exceptional long product life cycle of Rockdelta mats.

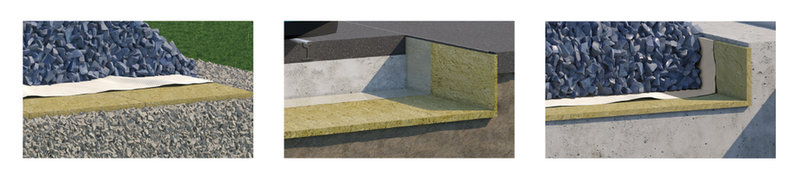

Vibration control for ballasted tracks | Vibration control for slab tracks | Structure protection for all track types

Why Rockdelta?

KNOWLEDGE LEADER

With over 80 years of production expertise creating valuable solutions from stone wool, and more than 40 years specifically in the railway sector developing resilient systems, our know-how is unmatched.

Reliable

Rockdelta mats are designed, tested and manufactured to have an extended lifetime with retained functional performance even under extreme conditions. This helps ensure the exceptional long product life cycle of Rockdelta mats.

Sustainable

All of our products and solutions are created from basalt, an all-natural and fully sustainable material. It’s safe to work with and is 100% recyclable – contributing to a circular economy. The end result is a stone-based solution that lasts a lifetime, improves safety, comfort and general well-being.

Interested to find out more?

Our new white paper provides insight into how Rockdelta stone wool mats work to control vibration and protect structures for rail tracks. It explains what properties make Rockdelta stone wool mats work more effectively compared to conventional organic materials currently used. Request your personal copy on our website.

About the ROCKWOOL Group

As part of the ROCKWOOL Group, we are committed to enriching the lives of everyone who comes into contact with our solutions. Our products are diverse and all contribute to shaping a circular economy, enhancing resource efficiency, and nurturing the safety, health and wellbeing of those who make and use our products.

Contact Us

Lapinus | ROCKWOOL B.V.

Delfstoffenweg 2, 6045 JH Roermond

The Netherlands

Tel: + 31 4 75 35 35 55

Mail: info@lapinus.com

Web: www.lapinus.com