Varsha Saraogi (VS): How does the technology work?

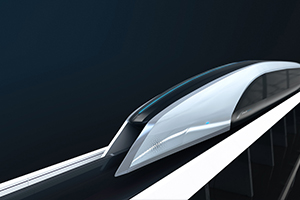

Thomas Bernin (TB): Spacetrain is an autonomous shuttle, which circulates in sustentation by means of air cushions on a reversed «T» track and is powered by hydrogen fuel cells. Its average circulation speed will equal around 540km/h.

To ensure the levitation of the module, the technology uses air compression – a high-performance cushion technology that guarantees a controlled consumption [of] 30kW combined.

The shuttle is propelled by linear induction motors, consisting of a primary fixed to the rolling stock - called the inductor - and a secondary made of ferro-metallic plates fixed to the monorail - the armature.

Hydrogen fuel cells use the electrochemical combustion of the gaseous dihydrogen with gaseous oxygen by simultaneously producing electricity, water and heat. Thanks to our hydrogen storage capacity, the shuttle can circulate 600km in autonomy. But it is very likely that this will increase in the years to come.

VS: What was your main goal when you came up with the technology of the Spacetrain?

A demonstration of the Adaptable Carriage

TB: At a time when the passenger transportation market in France is changing, we aim at offering an affordable solution capable of considerably reducing travel times between territories for a positive impact on the economic development of these regions.

With reference to the railway sector in France, rail transportation needed a refreshed and competitive model. The costs have become too high for railway company owners and operators, who are now degrading their service to users with issues such as the increase in the number of perturbations, decrease in frequency, connection closings, etc.

The Spacetrain Project gives an answer to this constraint by adapting to the existing rail network while proposing moderated costs of development.

VS: The train moves at the speed of 540km/h. Are there any risks?

TB: In circulation, it impossible for the train to derail because of the special shape of the railway.

Moreover, it will run outside, with no tube around and not in an [enclosed] environment, so it is very easy to leave the shuttle in case of emergencies. In those cases, we have emergency braking provided by carbon brakes which enclose the vertical part of the rail.

VS: What challenges do you face while testing the technology?

TB: We are testing each component - which comprise of air cushions, linear motor technology, energy management system on board - separately.

After testing those, we will fit them on our first prototype scale 1:2 - the one that was introduced on the Paris Bourget Air Show in June - and we will test that prototype before the end of the year, in a « T » track built in our laboratory close to Orléans.

A real size prototype would come after our project has a several-kilometres-long monorail. So the short-term step, just after a phase of primary tests with the scale 1:2 prototype is to find or build a several-kilometres-long monorail, and in parallel to raise funds to build the scale 1 prototype.

Our components are already being manufactured and sold in various places. For example, we sold our linear motors to Siemens, hydrogen fuel cells to Air Liquid. Spacetrain is an integration solution. But the main challenge is the system of energy management to optimise the energetic consumption of all these components.

VS: How does the technology tackle the issue of reducing emissions?

TB: Spacetrain is a zero-emission solution. The hydrogen fuel cells leverage the electrochemical combustion of the gaseous dihydrogen with gaseous oxygen, by simultaneously producing electricity, water and heat. Unlike hydrocarbons, the combustion of hydrogen is not accompanied by the release of carbon dioxide, which is why it gives the battery the label of a clean generator.

According to our research, if every trip between Orléans and Paris - which is about 130 km - was replaced by Spacetrain shuttle trips, it could save 32,500t of CO2 emissions per year.

VS: Do you plan to roll out the technology in other countries apart from France in the near future?

TB: We have many promising contacts with other countries, in particular, Asia, Africa and even the US.

Many countries want to develop their territory with a high-speed transport solution but costs of the existing solutions like for example Hyperloop projects, TGV or Maglev are too high. Spacetrain’s main advantage is its very low costs. In terms of construction, one kilometre of Spacetrain technology would be around €8m-€10m.

That is why many are particularly interested in Spacetrain.

VS: The French Government announced that they would be injecting €13.4bn into the rail sector, so where do you see the industry going?

TB: Most of the time, that financial aid benefits mainly large market players. But if the French Government - through various grant programmes - could encourage the Spacetrain project, we could develop our activity in France, and become the equivalent of Airbus of the Toulouse Region.