IN FOCUS Company Insight

Sponsored by Frauscher

Future-proofing rail: Frauscher’s CTO on modular control and digital integration

Frauscher Sensor Technology, a global pioneer in train detection and wayside object control, has been recognised as a Category Award Winner in the 2025 Railway Technology Excellence Awards.

Main image: An NH90 TTH of the Royal New Zealand Air Force. Credit: Gordon Arthur

DIVERSITY

MANUFACTURING LEADERSHIP

SAFETY

PERIMETER DETECTION

Will Laughton, Director at Perfect Bore Manufacturing, won the Diversity award for his leadership in restoring the UK’s sovereign defense manufacturing capabilities while championing diversity, inclusion, and workforce development within the industry.

Frauscher Sensor Technology’s latest innovation, the Point Control System, is redefining railway signalling with its modular design, EULYNX compliance, and integrated predictive maintenance. CTO Andrzej Bartnik explains how these advancements are enabling flexible upgrades, robust cybersecurity, and sustainable operations – empowering operators to future-proof their networks and accelerate digital transformation.

We are honored to receive the 2025 Army Technology Excellence Awards, which reflect our commitment to innovation and excellence in supporting the British Army with cutting-edge barrel technologies, and strategic growth.

Will Laughton, Director, Perfect Bore Manufacturing

Andrzej Bartnik, CTO, Frauscher Sensor Technology

“PRASA is the largest rail passenger transport system in Africa,” says Nokuthula Marjorie Ngonyama, group chief information officer of PRASA. “We have more than 22000km of railway track in the country and 490 stations. We take about 5.5 billion trips per annum on our network, so our operations are huge.”

To meet this increasing demand, PRASA has spent the past few years overhauling its network, embarking on an ICT strategy that covers connectivity and communication across all its operations and value chains. Since 2011, it has earmarked a total of $15bn to improve transport capacity and service quality, including 7,724 locomotive systems, signal systems in four regions, and wireless communications systems in three regions.

Railway Technology: Congratulations on the Product Launches award. What does this recognition mean to Frauscher Sensor Technology at this stage in the company’s journey?

Andrzej Bartnik: This award is a great recognition of our technological development and a strong confirmation of our strategic direction. As a trusted provider of object controller solutions, the launch of the Frauscher Point Control System at InnoTrans 2024 marked a major step in expanding our portfolio beyond train detection. It underlines our commitment to innovation and validates our focus on delivering safe and reliable object controller solutions for the global railway signalling industry.

Credit: Frauscher

Labelled the first optical-visual detection application in rail, PRASA’s new system enables full-process security detection by combining optical-visual linkage with an upper-layer integrated management platform to detect, report and acknowledge alerts.

Developed based on research into the current state-of-the-railways as well as an in-depth analysis of PRASA railway operations and needs, the solution uses intelligent vibration-sensing optical fibre, video AI, and video surveillance to deliver high stability and reliability in a range of scenarios, including strong winds and heavy rain.

RT: How does the Point Control System align with Frauscher’s broader vision for innovation and digital transformation in the railway industry?

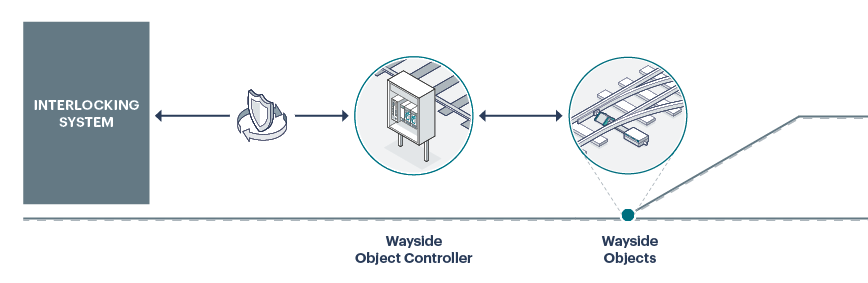

AB: The Frauscher Point Control System plays a key role in driving innovation and enabling the digital transformation of railway infrastructure. Our object controller solutions support the shift from traditional signalling systems to digitally controlled networks with decentralised interlocking technology, placing intelligence closer to the field elements.

By using standardised interfaces, the system acts as a technological link between point machines and interlocking systems. This approach enables the decoupling of component lifecycles and allows infrastructure operators to gradually modernise their networks without the need for full system replacement.

RT: EULYNX compliance is a key aspect of your solution. What were the main drivers behind your early adoption of these standards, and how do you see this shaping the future of railway signalling?

AB: Our early adoption of EULYNX standards was driven by the market need for interoperability, flexibility, and future-proofing in railway signalling systems. By complying with EULYNX, we ensure our solutions can be integrated seamlessly across different manufacturers and generations of equipment.

We clearly see that many players within the industry have aligned on this standard by now and share efforts in developing this further. This empowers modernisation and modular upgrades whilst reducing overall complexity. That said, EULYNX will significantly shape the future of signalling.

However, further solutions, such as our own Frauscher Safe Ethernet FSE protocol, will additionally support efficient ways of digitalisation in projects and markets not utilising the EULYNX specification.

RT: The system is designed for both new installations and upgrades of existing infrastructure. What challenges did you encounter in ensuring such flexibility?

AB: A key challenge was achieving operational flexibility by accommodating the wide variety of interfaces used by different point machines downstream. We needed to create a solution that unifies these diverse interfaces, simplifying lifecycle management and reducing efforts, spare parts complexity, and overall costs.

Another challenge was ensuring system modularity in order to serve a wide range of operational environments. The modular architecture of the system allows us to meet the requirements of both small stations and large, complex installations.

It can be configured either as a single object controller or as a multi-object controller setup, controlling up to 20 point machines through one communication channel. These point machines can control small turnouts independently or, when grouped in twos, threes, fours or more, can also control large-radius turnouts.

RT: Scalability and modularity are highlighted as core strengths. Can you share how this approach benefits railway operators in practical terms, especially in diverse operational environments?

AB: The Frauscher Point Control System is designed to be scalable and modular, allowing operators to adapt it to different station layouts. In widespread stations, object controllers can be distributed across several wayside cabinets, while in compact settings, multiple controllers can be combined centrally.

It also supports complex applications like large-radius turnouts with multiple point machines or combined control of elements such as movable frogs, all within one modular system design.

Despite these varied configurations, communication to the interlocking system uses a unified channel. This simplifies integration and reduces planning, installation, and maintenance efforts throughout the system’s lifecycle.

Credit: Frauscher

RT: Condition monitoring and predictive maintenance are increasingly important in rail operations. How has the integration of these features in your system impacted maintenance strategies for your clients?

AB: Our system integrates condition monitoring directly into the object controller, providing real-time data on the status and performance of point machines – without the need for additional measurement devices. This data is made available through standardised interfaces.

As a result, operators can transition from reactive to predictive maintenance strategies. Potential issues are detected early, allowing targeted interventions before failures occur. This reduces unplanned downtime, lowers maintenance costs, and increases overall system reliability.

RT: Cybersecurity and secure communication are critical in today’s connected railway networks. How does Frauscher address these concerns, and what feedback have you received from the market?

AB: Frauscher addresses cybersecurity concerns by synchronising safety and security lifecycles in the product development. For example, our Point Control System includes advanced security measures that enable its use in category 3 networks according to EN50159.

Feedback from the market has been positive, highlighting the importance of object controllers fulfilling both safety and security requirements. This allows railway operators to benefit from secure remote access for data retrieval and software updates, while maintaining strong protection against cyberattacks.

Credit: Frauscher

RT: The Point Control System is noted for its compact design and simplified installation. How do these attributes contribute to reducing project timelines and overall lifecycle costs?

AB: The compact design of the Point Control System minimises installation space, making it ideal for tight environments. Minimal cabling simplifies wiring on site, reducing project timelines as well as material and labour efforts. Maintenance and component replacement are also faster and easier.

Lower material use, small footprint, low energy consumption, and minimal heat generation reduce the system’s carbon footprint. Built-in cybersecurity with remote access further cuts wiring and on-site interventions. With a service life of up to 30 years, the system supports sustainable and cost-effective railway infrastructure.

RT: Is your system yet in operation somewhere round the globe and if there are any projects, what progress has been made so far?

AB: The most outstanding project so far is the “Digirail Project” in Finland. In cooperation with Mipro Oy, we are supplying our EULYNX-compliant object controllers for both point machines and train detection.

This is one of the first installations taking full advantage of the possibilities created by standardisation, which enables operators to split tenders and pick from a broader range of offers and solutions – a trend which we’re not only observing in Europe, but also many other global railway markets.

Within the project itself, a major milestone achieved so far has been the successful connection of subsystems and the interlocking, which marks a huge step towards full integration. Now we’re developing a mutual understanding of safety and security requirements and responsibilities to ultimately elaborate a common safety case, making sure the systems are protected as a whole.

RT: What’s your advice to railway operators and industry stakeholders considering the adoption of next-generation control systems?

AB: It’s important to start early with the adoption of next-generation control systems. Modern object controllers with standardised interfaces allow a step-by-step modernisation, enabling gradual integration without the need for full system replacements. This approach supports flexibility, reduces risk, and ensures a smoother transition to future-proof railway infrastructure.

Company Profile

Perfect Bore is a premier provider of precision engineering services. They pride themselves on being the UK’s solution to long diameter to length or complex bore detail components. Having over three decades of experience in manufacturing precision tubular components, they are well equipped to deliver the future projects in hand.

Their expertise extends to working with high-temperature corrosion-resistant alloys such as Inconel, Monel, Hastelloy, and stainless steels, meeting the stringent requirements of major original equipment manufacturers (OEMs) and sub-tier companies.

Perfect Bore is a key supplier to the aerospace and defence sectors, with its bore solutions present in components used by leading manufacturers like Airbus, BAe, Goodrich Actuation Systems, Boeing, Moog, and Rolls Royce in projects such as the B787 Dreamliner, A400M, and A350. The company is committed to quality and on-time delivery, adhering to ‘just-in-time’ schedules and lean manufacturing initiatives to provide cost-effective solutions.

Perfect Bore maintains a fully accredited integrated management system compliant with AS9100:D/ISO 9001:2015, ISO 14001:2015, and ISO 45001:2023, and is the NDA’s Supply Chain Charter for Nuclear Decommissioning Sites.

Jacky Wang, VP of Huawei's smart transportation business unit.

Contact information

Frauscher Sensor Technology Group

Gewerbestraße 1

4774 St. Marienkirchen bei Schärding

AUSTRIA

Tel.: +43 7711 2920-0

Email: office@frauscher.com

Web: www.frauscher.com

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes