MTM Power® has been a reliable and experienced partner of the railway sector for more than 25 years. The quality of innovative products as well as the flexibility and reliability of the company are the decisive factors. Sound technological and industrial knowhow are combined with the highest quality standards. Comprehensive experience over many years directly impacts on the development of new products - as well as the knowledge gained from the close cooperation with the normative committees and customers.

MTM Power Administration Building

MTM Power® offers a wide range of reliable and high quality electronic power supply products for the rail industry - for rolling stock and trackside applications. MTM Power® supplies railway projects throughout the world and is the preferred supplier to well-known manufacturers of locomotives, high speed trains, EMU´s and regional trains as well as metro trains. Just as insusceptible to mechanical stress such as shock and vibration as to environmental effects such as condensation, humidity and conductive dusts – the converters developed in accordance with EN 50 155, EN 45 545-2 are suitable for challenging rail operations and prove themselves time and time again throughout the world. They control the power supply to the control units of the air conditioning systems, window heating, under-floor containers, hygiene cabins, driver control terminals, doors and much more. They are an emergency start installation enabling the starting of vehicles without supplementary emergency batteries. Components of MTM Power® ensure infrastructure operations such as controlling barriers, signals, switches and platform access doors. They also ensure reliable communication in the vicinity of railway operations.

Railway Applications for MTM Power products

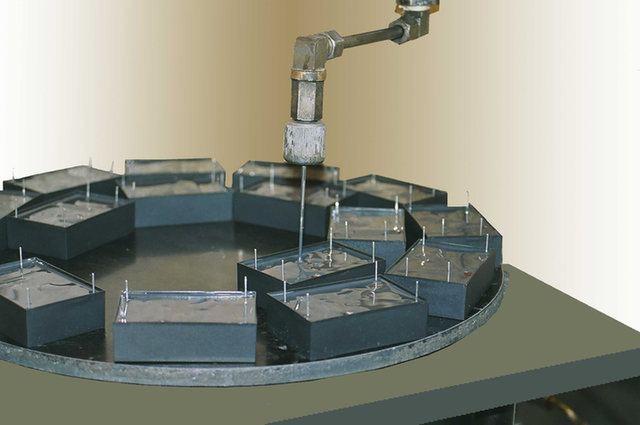

Compliance standards is ensured by a patented technology (EP 1 987 708, U.S. Patent Nr. 8,821,778 B2) of the Thermoselective Vacuum Encapsulation of the power supply units and the DC/DC converters. A ‘cemented joint’ is created between the electronics and the solid encapsulation material. The term ‘cemented joint’ originates from the licensing process for electric safety and describes the normative, proven durable and intractable capsulation. Ageing, heat, cold, rapid temperature changes or other environmental impacts are not to cause detachment, cracking or air pockets under any circumstances.

The thermal coupling of the components by the encapsulation material to the surface of the housing or base plate prevents the development of hotspots and economically guarantees a broadly homogenous temperature distribution in the power supply unit.

The high degree of efficiency and use of suitable materials for the housing guarantee to exceed the normative specifications for the touchable surfaces. A side effect of the technology used is a much higher IP degree of protection than similar encapsulated standard power supplies. The determining component finally is the interface to the outside relating to connecting the power supply to lines and loads.

Series PCMDS with 30 W - 400 W

The use of suitable plug connectors with a high IP degree of protection to the encapsulated power supply created power units permitting to be mounted locally where the power is needed. Protection against possible risks such as electric shock, fire or burning, mechanical damage or environmental effects is ensured by the power supply itself. The process of cooling the converter is achieved by thermal coupling through BPC (base-plate cooling) technology or –if needing– by adding a heat sink element.

Hence, all devices are especially designed to ensure the operational requirements under rough and critical conditions as well as complying with all the requirements and standards specific to railway operations. MTM Power® provides its customers the corresponding CoC´s for fire protection declaration, short reports of the DVT (design verification test) and on all railway operation products.

Encapsulation Machine

Contact Us

MTM Power® Messtechnik Mellenbach GmbH

Website: www.mtm-power.com

Email: info@mtm-power.com